Our People

- Over 25 Employees across the UK

- In house Design team including Mechanical, Software and Controls

- Resident maintenance teams and mobile services.

- In house Project delivery team.

Facility

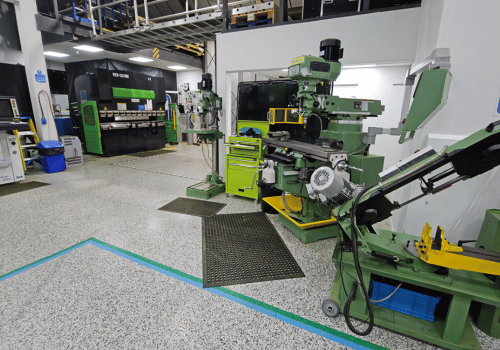

Our 6000 sqft facility in Chichester enables us to manufacture on demand in house. This includes conveyor manufacture and assembly, electrical panel building, design and testing. Having all skills and engineering under one roof enables our team to deliver complex solutions cost effectively and enables us to control the manufacturing process. We are also able to extensively test and conduct FAT with our clients. Through strategic partnerships, we benefit from extensive production capabilities and advanced testing facilities, enhancing our innovation and risk management efforts.

Products and services

- Turnkey solution design

- Electrical design (Eplan)

- Mechanical design 2d AutoCAD and 3d design solid works

- Controls design including commissioning

- CE and UKCA marking

- Electrical panel building

- FAT testing and demos

Engineering

Manufacturing

- Machining, turning, milling etc

- Welding

- Powder coating

- Laser cutting 3m bed

- CNC press brake for folding sheet metal

- CNC bending

Products

- Modflex -Pallet conveyor systems

- Modflex- Tote and Carton Conveyor

- Ori-Sort High speed wheel sorter

- High speed print and apply line

- Bespoke Conveyors and machinery

Project Delivery

- Project management

- CDM 2015 management including Principal Contractor and Principal Designer duties

- Mechanical Installation

- Electrical installation

- General labour provision

- Civils work

Aftersales

- Visited maintenance contracts

- Resident maintenance contracts

- 4-hour SLA to site

- Hotline support including 24/7 software dial in

- Access to a large network of engineers across the UK and Ireland

Previous projects

- Multiple Sorter Installations - Cross Belt, Bombay and tilt tray

- Inbound receive lines at multiple amazons feeding all pick towers throughout the building.

- Multiple E-commerce Frugality Projects

- E-commerce Maintenance Shutdowns dealing with Sortation and conveying systems

- Sketchers – Print and apply over 2 sites – Belgium and China

- British Gypsum – Goods lift and Conveyor System – Principal Contractor

- Siva – ASRS, AGV, Racking and Conveyor installation – Site Management for installation and commissioning – 8-month Project

- Chivas - ASRS, AGV, Racking and Conveyor installation – Site Management for installation and commissioning – 6-month Project

- Deployment and installation of robotic AMR solutions across multiple European sites.

- Chute extension projects for increase sorter capacity

- Automotive ASRS solutions

- High Speed print and apply lines

- Pharmaceutical Robotics

- Seat loading solution in automotive production facility.

- Expeditors - Pick to light system with G2P stations

- Gompels - Pack and Sort solution for outbound system