Introduction

In today's fast-paced, digitally driven economy, the demand for faster, more accurate, and scalable logistics is higher than ever. Businesses are turning to automated warehouse solutions to meet customer expectations while reducing operational costs. From robotics to AI-powered systems, warehouse automation is no longer the future—it's the present.

What Are Automated Warehouse Solutions?

Automated warehouse solutions refer to the use of technology—such as robotics, artificial intelligence (AI), conveyor systems, and software—to perform tasks traditionally handled by humans. These systems are designed to optimize inventory management, order fulfillment, storage, and shipping processes.

Key Components of Warehouse Automation

-

Automated Storage and Retrieval Systems (AS/RS):

Mechanized systems that automatically place and retrieve goods from specific storage locations. -

Robotic Picking Systems:

Robots equipped with sensors and AI can identify and pick items, improving accuracy and reducing labor costs. -

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs):

These vehicles transport goods throughout the warehouse without human intervention, using maps and real-time navigation. -

Warehouse Management Systems (WMS):

Software that provides real-time data on inventory, orders, and warehouse operations to streamline decision-making. -

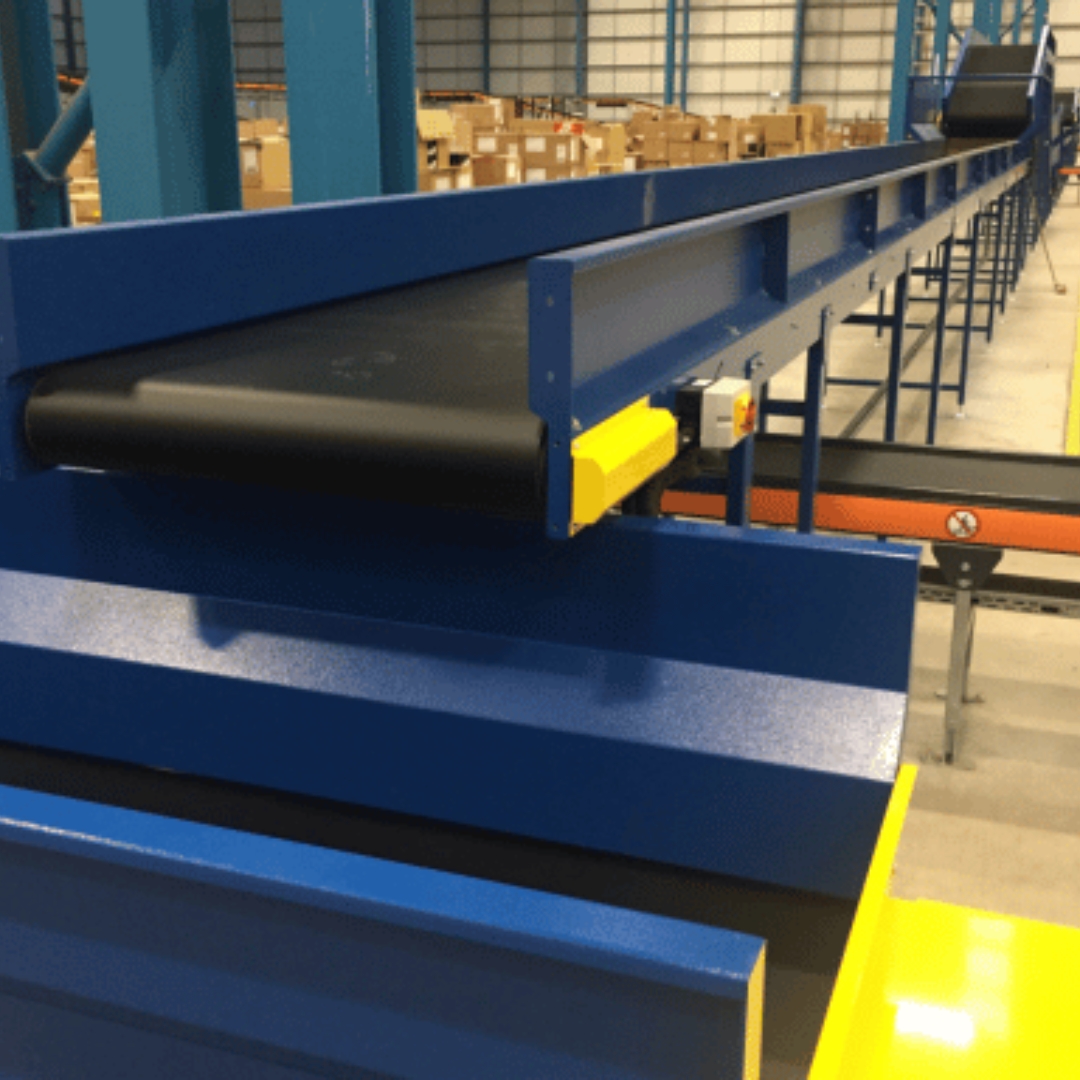

Conveyor and Sortation Systems:

Move products quickly and efficiently through the warehouse, sorting them automatically based on size, weight, or destination.

Benefits of Automated Warehouse Solutions

-

Increased Efficiency:

Automation reduces the time required for order picking, packing, and shipping. -

Higher Accuracy:

Fewer human errors mean better inventory tracking and order accuracy. -

Scalability:

Systems can adapt to growing business needs without a corresponding increase in labor costs. -

24/7 Operation:

Machines can work round-the-clock, ensuring continuous operations and faster fulfillment. -

Safety:

Reduces the risk of workplace injuries by taking over dangerous or repetitive tasks.

Industries Leveraging Warehouse Automation

-

E-commerce – Fast, error-free order fulfillment is critical.

-

Retail – Optimized inventory turnover and seasonal scalability.

-

Pharmaceuticals – Precision in storage and compliance is key.

-

Manufacturing – Efficient raw material and component handling.

-

Food & Beverage – Time-sensitive inventory and cold storage automation.

Challenges in Adopting Warehouse Automation

While the benefits are clear, the implementation of automated systems comes with challenges:

-

High Initial Investment

-

Integration with Legacy Systems

-

Employee Training & Change Management

-

Maintenance and Downtime Risk

However, the long-term ROI and competitive advantage often outweigh the initial hurdles.

The Future of Warehouse Automation

With advancements in AI, machine learning, and IoT, automated warehouses are becoming smarter and more autonomous. Predictive analytics, drone inventory checks, and AI-driven demand forecasting are setting new benchmarks for operational excellence.

Conclusion

Automated warehouse solutions are not just a trend—they're a necessity for businesses looking to scale efficiently, reduce costs, and stay competitive in a digital-first world. Whether you're a logistics company, retailer, or manufacturer, embracing automation can transform your supply chain from a bottleneck into a powerhouse.